Although it has a habit of being slow to embrace innovation, the sector of large, complex civil infrastructure is progressively changing its ways as the benefits to be gained from the latest technology become more evident.

Whether it be drones, robots, software or sensors, contractors are starting to embrace innovation that not only improves efficiency and productivity but also increases the safety of their workers. It is the kind of innovation that began with the likes of building imagery modelling. Also known as BIM, it is software that facilitates the planning, designing and building of structures.

Ubiquitous drones

Drones, perhaps one of the most ubiquitous technological developments of recent years, have proven to be useful in surveying and monitoring projects at every stage of development. They are being used by project managers to observe their workers remotely and make sure they are doing things properly as well as obeying safety standards.

Having drones hover over a construction site taking images and gathering data eliminates the need to send teams of inspectors, thereby saving time and money. Drones feed information in real time to managers to enable them to identify lapses, weaknesses or failures that could result in an accident. When they are mounted with three-dimensional lasers, drones can examine the accuracy of the measurements of materials and structures like pillars. They eliminate the need for humans to put themselves in dangerous angles or positions, sometimes at perilous heights, to do the same work.

Futuristic exoskeletons

Although it seems more appropriate for the set of a futuristic film, the exoskeleton is making an appearance at work sites. It is a robotic suit that is fitted to the body of a worker to enhance his or her strength and resistance. It can allow him or her to lift heavy objects without straining and do it for longer stretches of time, reducing back pain and other muscle problems. A 2015 article by Wired magazine describes how a California company called Ekso Bionics created one that allows the worker to lift heavy tools as if they were weightless.

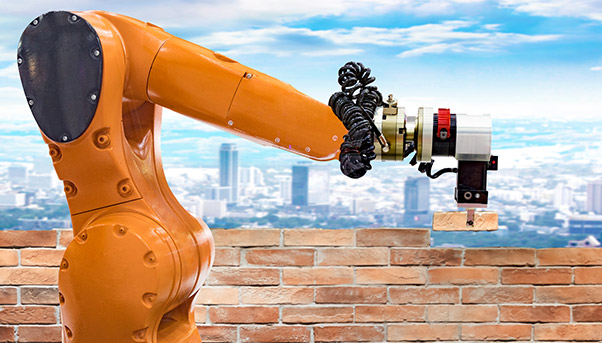

Repetitive movements, meanwhile, can be as harmful to the body as the lifting of heavy objects. Construction Robotics, for example, has developed the SAM 100 to eliminate the need for humans to do the most mundane part of brick-laying. As the robot builds a wall, humans can focus on tasks that require greater skill and pose less risk to their health. Another example is Noah Ready-Campbell, founder and chief executive of Built Robotics, who has developed technology that enables bulldozers to operate autonomously. «Robots basically do …work (that) is more repetitive, more dangerous, more monotonous», he once told Associated Press, a U.S. news agency.

Training simulations

Training also enhances safety on the construction site, and virtual reality is helping make it more effective. By offering simulations of the conditions faced on site, this technology can prepare people for the work that will be expected of them, such as operating big cranes.

An extension of that is augmented realty, which displays information on a set of glasses worn by a worker. By superimposing graphics onto the view of the real world seen by the wearer of the glasses, it helps reduce risks by highlighting hazards in the execution of complicated processes. When combined with virtual reality, a scan of a structure by the wearer of the glasses can confirm if it was built according to plan by comparing the finished project with the original design and identifying any differences between them.

Wearable safety

Apart from eyewear, wearable technology also comes in the form of a vest with an inflatable collar to project the neck and head should the wearer fall from a great height. Then there are hard hats with a beacon that alerts supervisors where all of their workers are located. It makes it easier for them to be found if, for example, they fall unconscious or need to be evacuated because of the leak of a harmful gas in a tunnel that is being excavated. Sensors in work clothes can monitor breathing, body temperature and heart rate. They can also alert supervisors if there is a lack of movement on the part of a worker, who might have fallen unconscious but remains unseen by his or her colleagues on the site.

Sensors can also be installed throughout a construction site to monitor the conditions of the environment like dust, temperature, noise and other elements like gases that can harm workers, alerting them when something goes amiss. There are also those, for example, that warn road workers when they go beyond a perimeter and risk stepping into traffic.