In narrow streets of Certosa, the Genoa neighborhood that on August 14, 2018 witnessed the collapse of the Morandi bridge right before its very eyes, they say that the new bridge appears at a certain time each day as if it were already finished.

Every evening at 7:30 PM, people living on Via Walter Fillack and the surrounding streets watch from their windows as a beam of green, white and red light crosses the Polcevera valley following the trajectory of what will become the new bridge.

The beam is a tribute to Genoa and all of Italy as the country fights to stem the tide of Covid-19. Now after months of work, the new bridge itself has finally appeared on the skyline of the valley. The concrete and steel structure was designed by Renzo Piano, projected by Italferr and built in record time by Webuild (which is working with Fincantieri in the PerGenova joint venture).

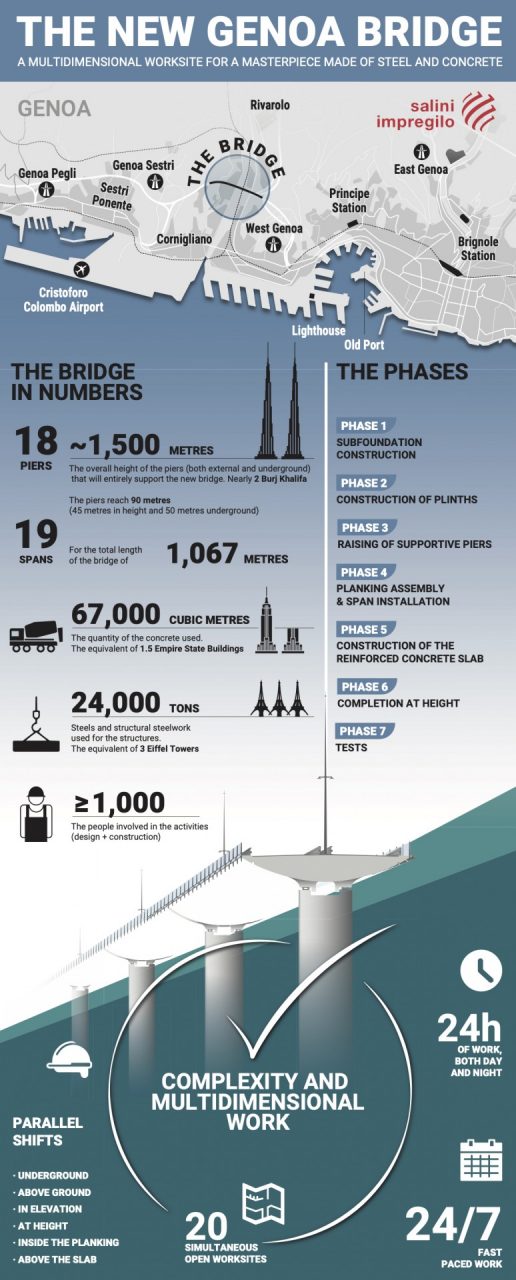

The last-but-two of the bridgespan’s 19 sections has recently been completed, bringing the full length to just over a kilometre (0.62 miles) and just short of the 1,067 metres (3,500 feet) covering the distance between east and west uniting the valley’s mountains.

The makes the bridge seem close to completion, even from the streets of Certosa.